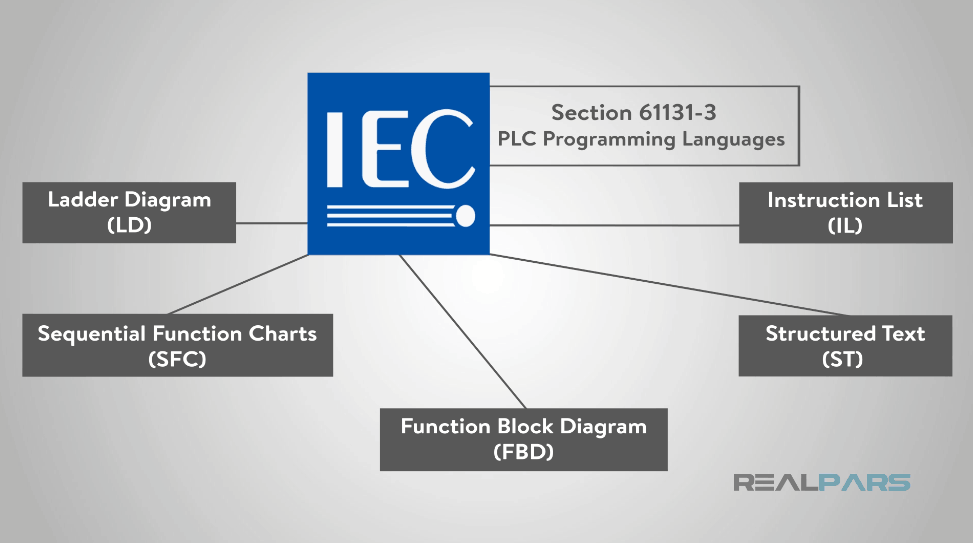

There are 5 programming languages that are part of the IEC 61131-3 standard (International Electrotechnical Commission). This IEC standard establishes fundamental rules for standardizing PLCs and their programming languages. Let’s take a closer look at all these popular PLC programming languages.

İçindekiler

What Are the Most Popular PLC Programming Languages?

The 5 Most Popular PLC Programming Languages:

- LD – Ladder Diagram

- SFC – Sequential Function Charts

- FBD – Function Block Diagram

- ST – Structured Text

- IL – Instruction List

Let’s start immediately sharing information about the PLC programming languages listed above.

Before we begin, we also recommend reviewing our article on PLC Data Types, which is the foundation of PLCs.

Ladder Diagram (LD)

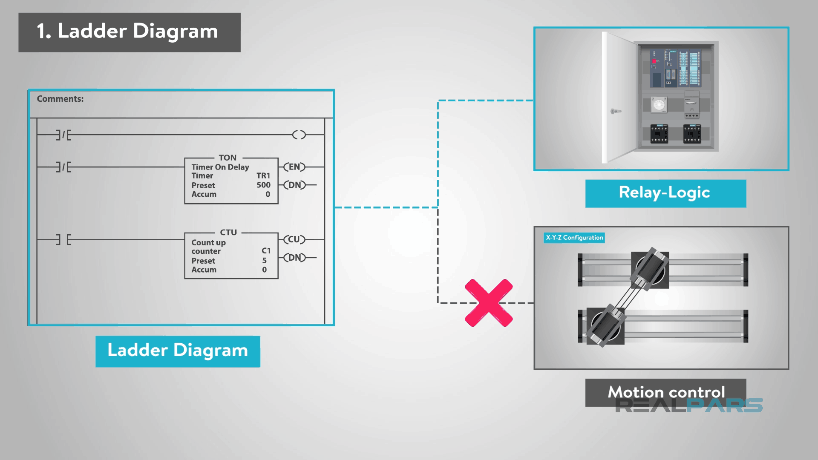

Ladder Diagram was originally modeled from relay logic, which used physical devices like switches and mechanical relays to control processes. Unlike physical devices that require an electrical signal to activate them, Ladder Diagram uses internal logic to replace all but the actual physical components.

Ladder Diagram is constructed with horizontal rungs between two vertical rails, representing electrical connections in relay-logic schematics. Whether logical or physical, you can program all necessary input conditions to influence the output conditions.

Ladder Diagram Advantagesı

The primary advantages of the Ladder Diagram language are as follows:

- The rungs are organized and easy to follow.

- It allows documentation with easily visible comments.

- It supports online editing very successfully.

Ladder Diagram Disadvantagesı

The main disadvantage is its limitations in handling motion or group-related operations efficiently.

The next PLC programming language is Sequential Function Charts (SFC), a graphical programming type.

Sequential Function Charts (SFC)

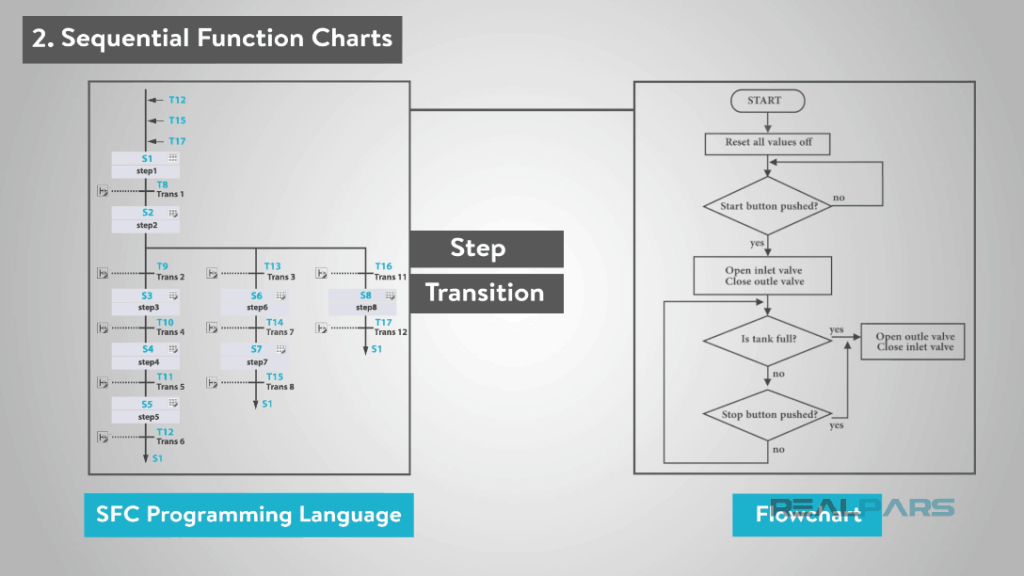

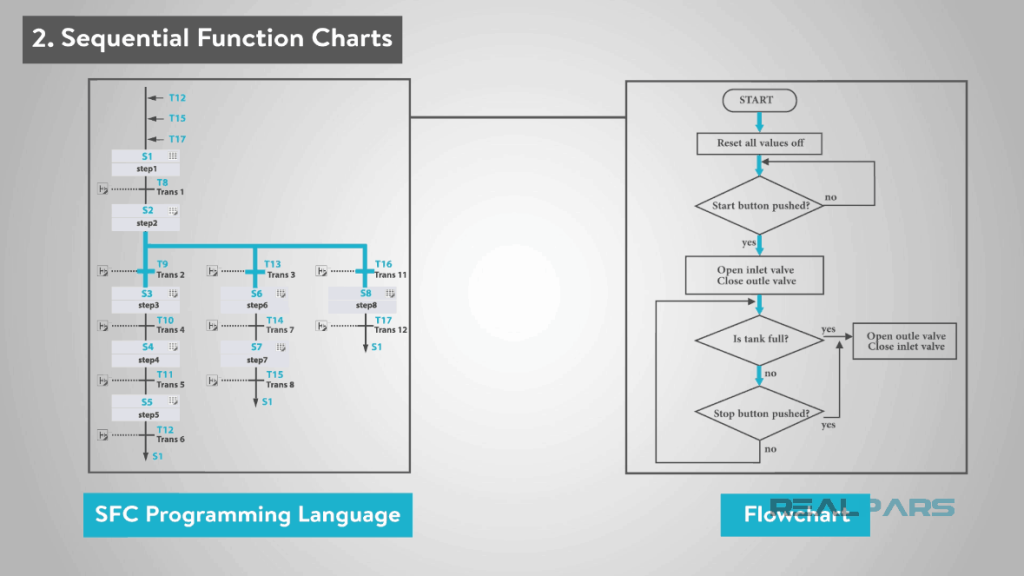

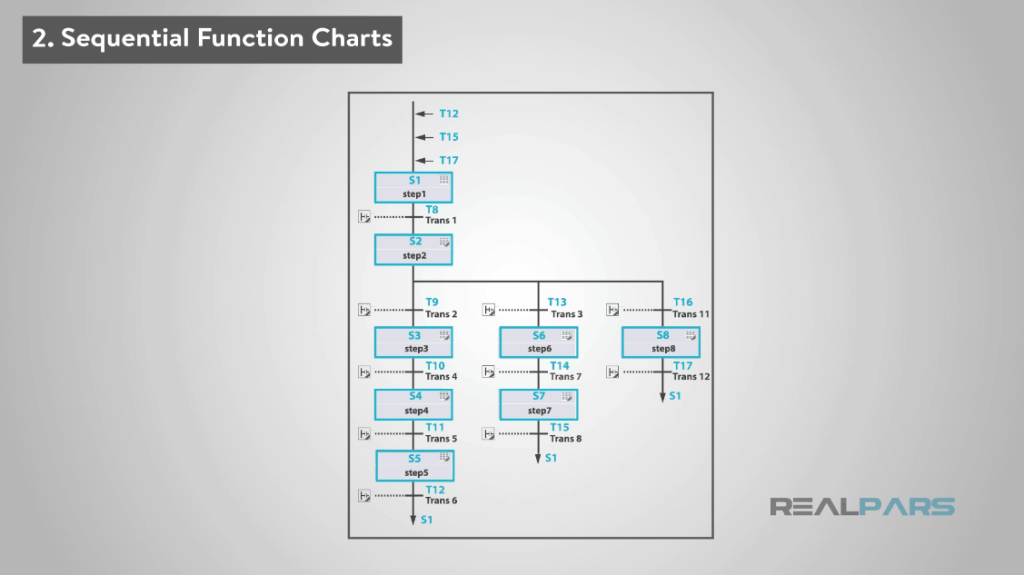

If you have any experience with flowcharts, this PLC programming language will feel familiar. In Sequential Function Charts (SFC), you use steps and transitions to achieve your end results.

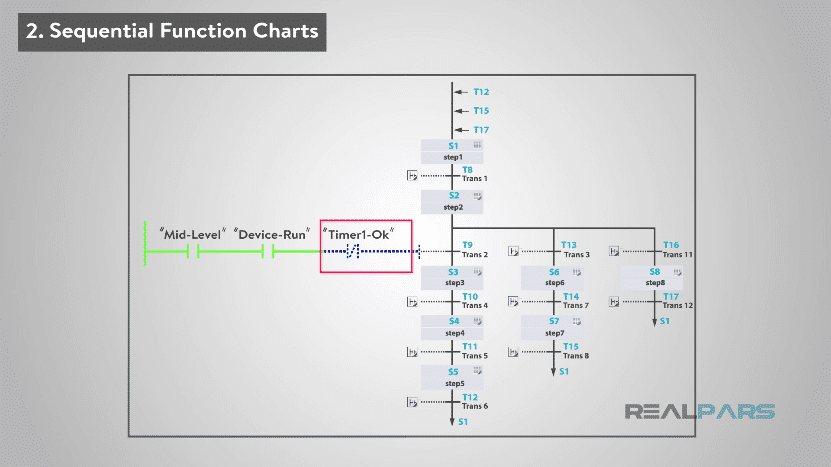

Steps serve a critical function in your program. These steps contain actions that occur when you program them to be executed. This decision may be based on timing, a specific phase of the process, or the physical state of equipment.

Transitions are the instructions you use to move from one step to another by setting true or false conditions.

Unlike traditional flowcharts, Sequential Function Charts (SFC) can have multiple paths. You can use branches to initiate multiple steps simultaneously.

Advantages of Sequential Function Charts (SFC)

Some key advantages of Sequential Function Charts include:

- Operations can be broken down into major steps, making troubleshooting faster and easier.

- You have direct access to the logic to see exactly where an equipment failure occurred.

- The ability to use repeated executions of individual logic segments can make designing and writing the logic faster.

Disadvantages of Sequential Function Chartsı

Even when considering the advantages of Sequential Function Charts (SFC), this PLC programming language may not always suit every application.

Now, let’s move on to our third PLC programming language.

Function Block Diagram (FBD)

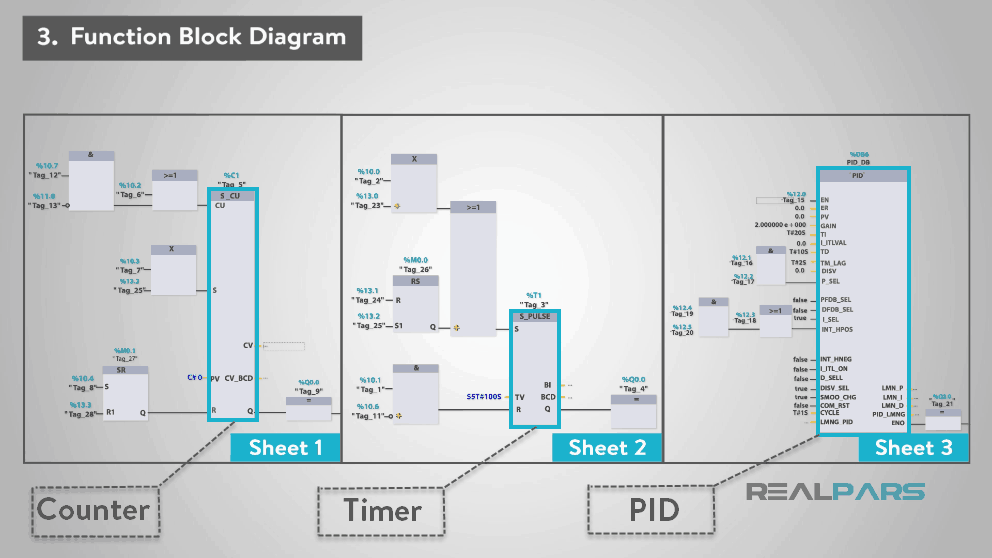

Function Block Diagram (FBD) is also a type of graphical language. It describes a function between inputs and outputs connected by lines in the form of blocks.

Function Blocks were initially developed to create a system where common, repeatable tasks—such as counters, timers, PID loops, etc.—could be easily implemented.

You program the blocks onto pages, and then the PLC continuously scans these pages in numerical order or follows the connections you programmed between the blocks.

Function Block Diagram Advantagesı

- Function Block Diagram works well with motion control.

- The visual method is easier for some users.

- The greatest advantage of Function Block Diagram is that you can condense many lines of programming into one or a few function blocks.

Function Block Diagram Disadvantages

Since function blocks can be placed anywhere on the page, code written in this PLC programming language can become disorganized.

This can also make troubleshooting more difficult.

Structured Text (ST)

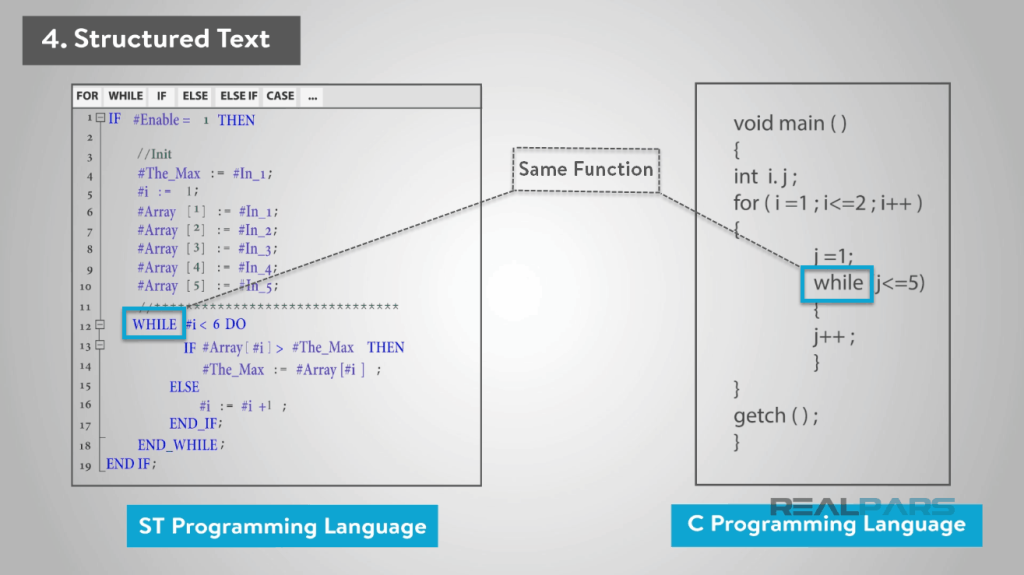

The fourth PLC programming language is Structured Text (ST), a text-based language.

Structured Text is a high-level language similar to Basic, Pascal, and C.

It is a powerful tool capable of performing complex and repetitive tasks using algorithms and mathematical functions.

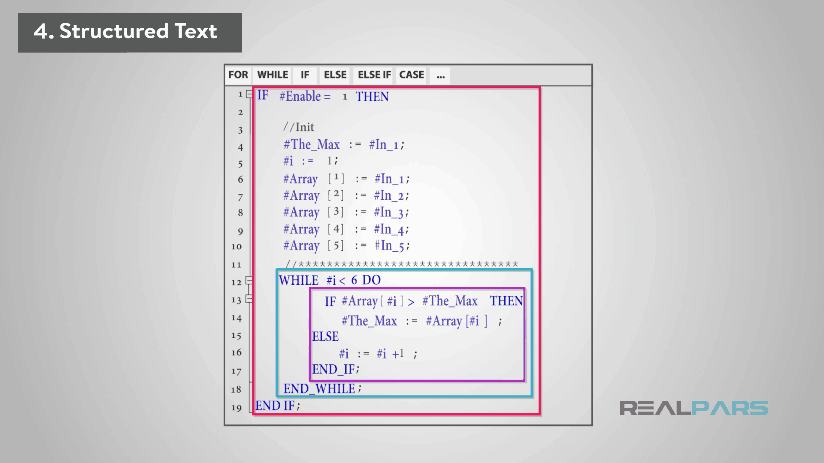

The code uses statements separated by semicolons, and inputs, outputs, or variables are modified by these statements.

You must write every line of code, and it uses functions such as FOR, WHILE, IF, ELSE, ELSEIF, and CASE.

If you have experience with Basic or C languages, this PLC programming language will feel easier than some other types of PLC languages.

Structured Text Advantages

- It is highly organized and excels at handling large mathematical calculations.

- It allows you to incorporate certain instructions that are not available in some other languages, such as Ladder Diagram.

Structured Text Disadvantages

- The syntax can be challenging.

- Debugging is difficult.

- Online editing is cumbersome.

Instruction List (IL)

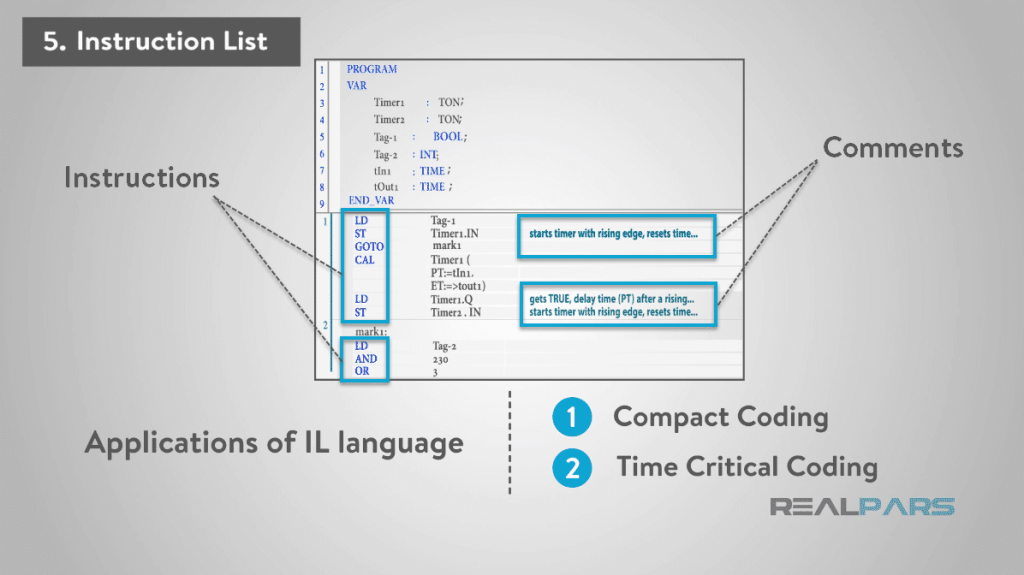

Now, let’s explore the fifth and final PLC programming language: Instruction List (IL).

Instruction List is also a text-based language, similar to Assembly Language. When using this PLC programming language, you will work with mnemonic codes such as LD (Load), AND, OR, and others.

Instruction List consists of instructions, each on a new line, along with any comments you may want to add at the end of a line for clarification.

Advantages of Instruction List

The Instruction List language is valuable for applications requiring compact and time-critical code.

Disadvantages of Instruction List

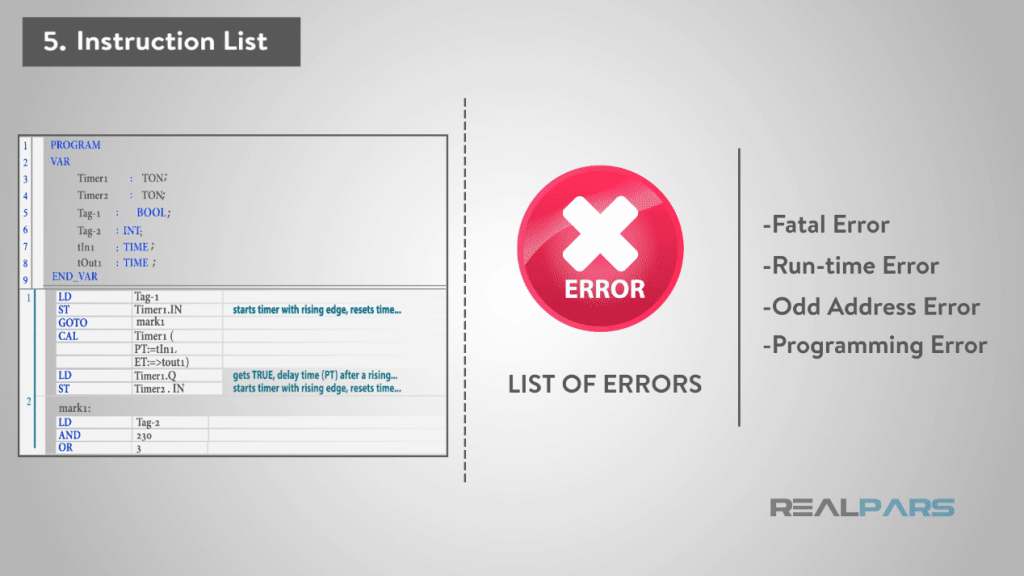

The main disadvantages of this PLC programming language are as follows:

- There are limited structuring possibilities, one of which is the “Goto” command.

- Additionally, compared to most other languages we reviewed earlier, it can contain many errors that are more challenging to manage.

So, have you decided which PLC Programming Language you think is the most popular?

After reviewing many analyses and opinions, as well as drawing from my own experience, Ladder Diagram (LD) is by far the most popular PLC programming language.

The primary reason for this is that the Ladder Diagram language naturally mirrors the technological evolution from physical relay logic to digital and logical systems. This allowed engineers and skilled workers to seamlessly adapt to this transition, troubleshoot issues, and maintain systems effectively.

In summary, there is certainly a place for all the PLC programming languages we’ve discussed. Your background, experience, and the specific application you’re working on will ultimately determine which PLC programming language is the right choice for you.

En Popüler PLC Programlama Dilleri Hangileridir?

Tüm detaylarını öğreneceğiniz PLC Programlama Dillerine ait videoyu da inceleyebilirsiniz.